company

Fields of activity

Sales

Customer contact, cost estimation, preliminary designs, offersPurchasing

Technical procurement, order-related material procurementDesign and Engineering

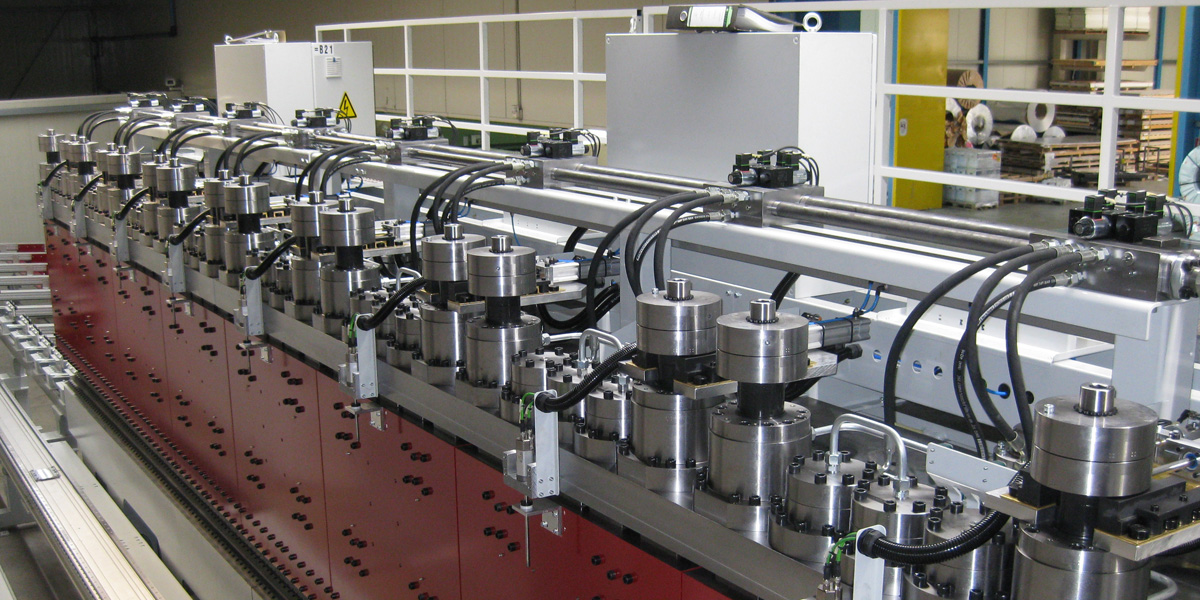

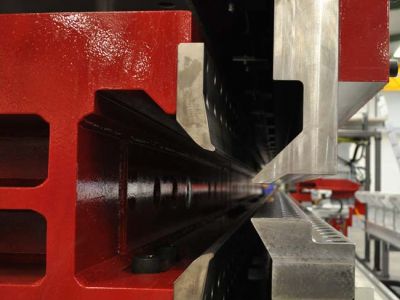

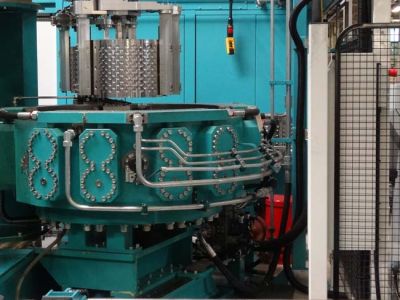

Machine conceptualisation, engineering drawings with CAD, component layout and hydraulic and pneumatic designElectrical Department

Circuit diagrammes, switch cabinets, laying electrical lines, assembly and system start-upMachining Centre

CNC milling, CNC lathe, surface grinding, erosion, bending and stampingAssembly

Installing components as to plans until complete machine is assembled, hydraulics and pneumatics, on-site system start-upDocumentation

Producing user handbooks as well as CE documentationSoftware development

SPS programming, user control panels, databank programming, computer control systemsService

Diagnostics, maintenance, repair, advisingReferences

Careers

Education and job training

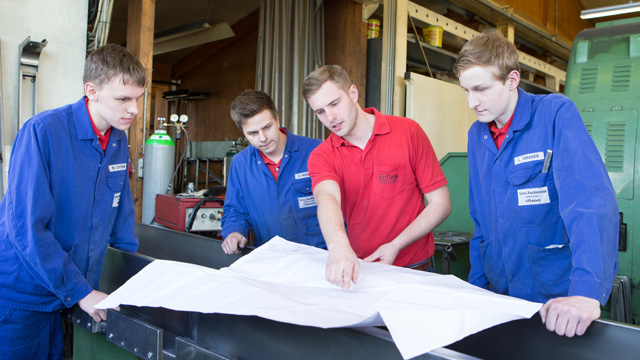

We place a lot of importance on the education and career-start of young, skilled workers. We train and educate for the occupations of precision mechanics, electronics specialists for automation, and technical product design. Currently we have 15 young men and women undergoing apprenticeships. We maintain close contact with local education institutes in the region. There is active cooperation with the von-Ravensberg-Schule in the neighboring town of Bersenbrück and with the August-Benninghaus school in the town of Ankum.

Internships

For students of lower, middle and upper secondary schools internships are offered. We also gladly offer internships to young adults with A-Level examination to get the admission to technical curriculum. We also support in-house engineering dissertations, graduation theses for technical educations, practical semesters and internships in the fields of mechanical building and electrical technology.

Career

We offer skilled workers in the fields of CNC machining, precision mechanics and electrical technology an attractive work environment. In the design department, experts work in the fields of mechanical engineering, machine building technology and engineering product design. In software programming we mainly have electrical engineering specialists. Occasionally we search for new employees for our special departments or administration.

We would be pleased to receive your application!

Please send your complete documentation by postal service to our address, or as a PDF file to: This email address is being protected from spambots. You need JavaScript enabled to view it.. Please feel free to call us if you have questions!